Perten Glutomatic® 2000 System

The world standard for gluten quantity and quality determination. When baking bread and producing noodles or pasta, the flour gluten content and strength will determine the quality of the finished product. The Perten Glutomatic® System is the world standard for determination of gluten quantity and quality.

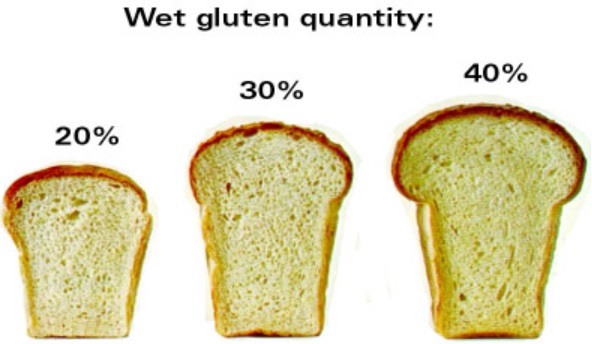

The effect of gluten quantity and quality in the flour used for breads, cookies, crackers and pasta is dramatic. In the photo of bread loafs above it is clear that the wet gluten quantity of the flour strongly influences bread volume. Using the Perten Glutomatic System you will be able to determine the baking quality of wheat and flour.

The Perten Glutomatic System consists of:

- Perten Glutomatic 2000

- Gluten Index Centrifuge 2010

- Glutork 2020

Features and Benefits

The Perten Glutomatic System is used worldwide by thousands of grain traders, flour millers, breeders and pasta/noodle manufacturers, who benefit from its features.

- Determine gluten quantity and quality - Improve the quality of your finished products by making sure that your raw materials meet gluten specifications. Higher wet gluten content means higher bread volumes.

- Official world standard - For international wheat and flour trade, gluten quantity and quality by the Perten Glutomatic System are typically specified. Make sure that buyer and seller agree by using the international standard. Approved according to the following standards:

- AACC 38-12.02

- ICC/No. 137/1, 155 & 158

- ISO 21415-2, 21415-4

- GBT 5506.2, 5506.4

- IRAM 15864

- CCAT Method 13

- Easy to use –Automated, easy to handle instrument with large touch screen guiding the operator through the analysis. Confidently operated by non-technical personnel.

- For flour and grain - Using Perten Glutomatic you don't have to produce a flour to determine the gluten characteristics for a wheat. You save time and costs as the Gluten Index method works both for flour and for ground wheat.

- Rapid analysis - A complete test takes less than 10 minutes.

- Determines true gluten - While gluten is correlated to protein, there are a number of cases where a wheat would have a high protein content, but no or very weak gluten. Perten Glutomatic is the only way to know for sure.

- Connectable – Perten Glutomatic has communication ports for the Centrifuge 2010, a balance and for connection with LIMS/PC.

Applications

The quality of dough-based products such as breads, pasta or noodles is highly dependent on the gluten quantity and quality of the flour. This means that everyone in the wheat chain, from breeder to baker, benefit from analyzing and controlling gluten properties with the Perten Glutomatic System.

- Breeding - By measuring the functional properties of protein at an early stage - without having to extract flour - breeders can select the appropriate wheat classes for further breeding and refinement.

- Grain Trading and Handling - The ease of use and the speed of the method enable the user to classify the incoming wheat based on gluten quantity and quality, essential for maximizing trade margins and supplying products suitable for varying end-use purposes.

- Flour Milling - Millers can blend flour to meet end-user demands while not selling high quality product at a low price thereby improving operating margins. With the Gluten Index, the Wet Gluten Content and the Falling Number analysis results available, millers can quickly predict the final baking quality, reducing the requirement for test baking.

- Baking - The gluten properties and structure are important to:

- Form elastic dough

- Retain gas during fermentation and baking

- Allow expansion

- Carry expansion

- Retain the shape of loaf

As baking quality is both related to starch and protein characteristics, a combination of the results from the Perten Falling Number® and Perten Glutomatic tests can be used to predict the baking quality. With the Gluten quality and quantity information at hand, bakeries are able to use the most cost effective grade of flour while still meeting end user quality. Maximizing the use of high quality flour and minimizing addition of expensive vital gluten results in substantial savings.

- Durum and Pasta - The Gluten Index is reported worldwide in crop reports as an important quality indicator. During pasta manufacturing, gluten has great influence in:

- Forming non-sticky dough

- Achieving desired processing characteristics

- Maintaining firmness and cooking stability

- Obtaining products with desired cooking characteristics

About gluten

Gluten is the functional component of protein and determines many dough and processing characteristics of wheat and wheat flour.

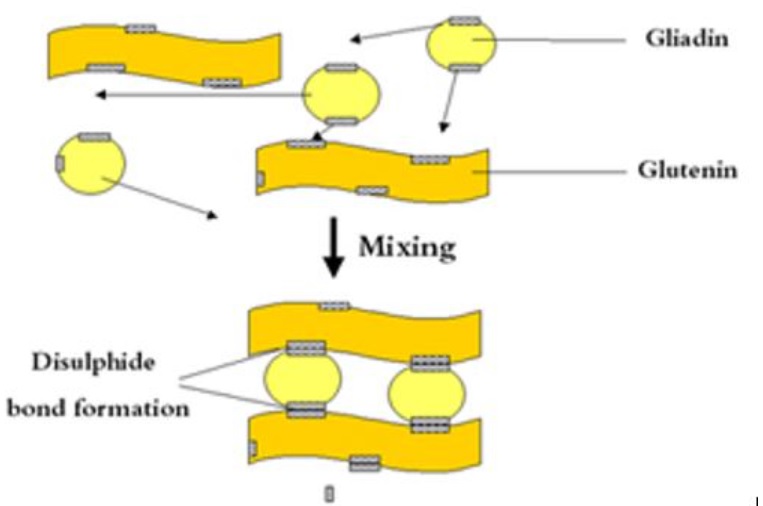

Gluten consists of the two proteins "Glutenin" and "Gliadin". It is not until a dough has been made that they actually form gluten. This is why it is not possible to determine gluten in wheat without actually making a dough. Flour, water and the energy from the kneading are all needed for gluten to form. A disulphide bond is then created between the glutenin and the gliadin as illustrated in the picture below.

The protein content is a purely quantitative analysis that may or may not be indicative of protein quality. While gluten content and protein content are correlated, there are situations during which protein content will not be indicative of quality. These situations include:

- Variable Growing Conditions

- Yearly Growing Variation

- Wheat Varietal Variation

- Wheat or Flour Blends

- Heat Damage

- Bug Damage

- Enzymatic Addition

It is under these conditions when the reported protein content is not indicative of quality that another set of tests is required. The Perten Glutomatic system is designed to measure protein quality for the following parameters:

- Wet Gluten Content

- Dry Gluten Content

- Water Binding of Gluten

- Gluten strength by Gluten Index

Specifications

General

- Power requirements: 115/230 V, 50/60 Hz

- Power consumption: Glutomatic 2000 250 VA / Centrifuge 2010 110 VA / Glutork 2020 875 VA

- Touch screen (GM 2000): 7 inches, capacitive

- Interfaces: 3x USB type A, 1x USB type B, 1x micro USB (service only), 1x ethernet connection

- Dimensions (HxDxW): Glutomatic 2000: 378 x 353 x 288 mm, Centrifuge 2010: 203 x 270 x 224 mm, Glutork 2020: 90 x 255 x 200 mm

- Net Weight: Glutomatic 2000 18 kg / Centrifuge 2010 7 kg / Glutork 2020 2 kg

- Ambient temperature: 5-35 °C

- Humidity: 35-80% RH, non-condensing

Analysis

- Products: Wheat, wheat flour, durum, semolina, vital gluten

- Parameters: Gluten Index, wet gluten content, dry gluten content, water binding in gluten

Recommended accessories

Laboratory Mill 3100 or 120. For Rapid and convenient grinding of whole wheat to wheat meal.