Optimize your process with real-time NIR measurements

Many food and agricultural processing operations have the potential to improve several aspect of their operations through accurate, timely knowledge of their production processes, and product characteristics. While manual sampling and analysis is useful, it takes time and only provides a snapshot at that instance. The DA 7350 In-line NIR sensor provides continuous, simultaneous measurement of parameters such as moisture, protein, fat/oil, ash and much more. This real-time measurement enables automated process control and helps companies worldwide optimize processing, reduce scrap and re-work while improving product consistency and quality.

Feature and Benefits

• Real-time measurements

• Industry 4.0 Ready

• Integrated camera

• Rugged design to suit production environments

• Easy integration through standard industry communication interfaces

Applications

Measure granules, pellets, flours, meals, powders, pastes, syrups, flakes, liquids and more.

The most commonly measured parameters are moisture, protein, ash, fat/oil, fiber and starch.

The DA 7350 can be mounted on pipes, hoppers, conveyors, mixers, at the entrances of a product stream, at its outputs, before or after dryers, before packaging or at other critical points in the process.

Flour Milling Maximize flour extraction through accurate real time ash measurements. Blend wheat types to reach correct protein content and save on higher priced raw materials. Control and optimize gluten addition

Starch Production and Corn Milling Optimize moisture inclusion and save on raw materials and energy by monitoring and controlling the dryers. Control the starch/gluten separation and avoid costly giveaways.

Oilseed Processing Measure oil in meal for optimized extraction. Increase yield by optimising protein content in the soybean meal through controlling the hulls add-back. Optimize the moisture inclusion, while remaining within specifications.

Dairy Processing Increase yield and reduce energy costs when spray drying milk powder by monitoring product moisture in real-time. Minimize grade change-over time and reduce waste; monitor black particles. Optimize the fat/moisture content of butter.

Modern technology that delivers

Integrated camera

Color measurement An integrated digital camera measures color. The dedicated lighting provides optimal conditions for color measurement enabling superior repeatability and improved alignment with laboratory methods. The standard color measurement according to CIE LAB space produce L*, a* and b* results. The example shows the measurement of Durum semolina.

Speck Count The DA 7350 includes speck counting as standard, which helps flour millers detect cloth breakages quickly. Specks can be classified by size and contrast in up to 16 different groups. By configuring alarms you can be notified immediately in case speck count exceeds set limits.

Real-time Process View Users can access real-time images of the process from any networked computer – be it in the next room or 1,000 kilometers away from the instrument. The images can be incorporated in to control system user interfaces and displayed in real-time. The images provide a unique, real-time view directly into the process stream. Operators can immediately detect presence of foreign material, visible defects, product color changes, and blockages. The system can be set up to automatically capture images of the product at various intervals..jpg)

Systems Integration

Great importance is placed on connectivity capabilities to communicate with existing plant control systems. We support many interfaces including: OPC UA, PROFINET, Modbus TCP, Fieldbuses and more. Benefits of integration in existing plant control systems:

• Implementation of automatic control loops is easily achieved

• Measurement information is presented in the familiar environment of the operators GUI, where it’s most needed

• Measurement results are easily incorporated in standard batch reports and continuous data archiving for audits, tracking, and tracing purposes

Modern, intelligent instrument software

Internet of Things and Industry 4.0 bring huge benefits, but require that sensors and other equipment are prepared for it. Process Plus is a modern, dedicated web-based process instrumentation software. It is an easy to use software designed with the specific demands of the process industry in mind. The software includes a web-based user interface with both numerical and graphical displays. Owing to the web based architecture, you may use as many operator stations as you require, without the need to install additional software or licenses. Process Plus includes communication interfaces compatible with IoT and Industry 4.0.

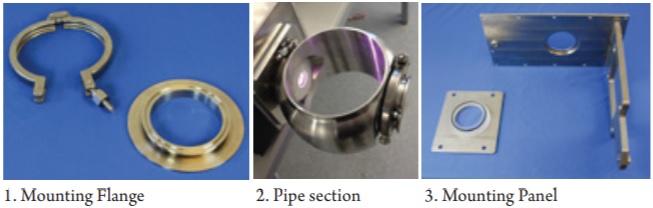

Accessories

We offer a ranged of mounting accessories to facilitate easy installation

1. Mounting Flange is a stainless steel flange for welding on to customers machines. This offers a highly flexible option, and provides a safe and easy instrument mounting.

2. Pipe section for slurries, pastes and suspensions to be insert in to existing pipe works.

3. Mounting Panel is a flexible and easy-to-use mounting option for conveyors and other flat surfaces